This bandsaw has been replaced by another model - ARG 260 plus E

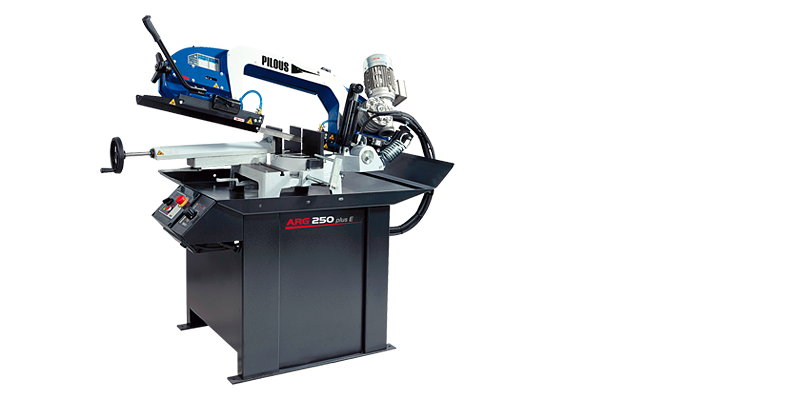

ARG 250 plus E

We confirm receipt of noncommittal demand

Demanded machine: ARG 250 plus E

Company:

Kontaktní osoba:

VAT:

Adresa:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to websiteWarning: Inactive model.

Universal band saw is appraised for general use in continuous uninterrupted production plants and in workshops (work on locks, maintenance) as well. Industrial band 27 x 0.9 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel.

The band saw arm uplift is manual; the feed into cut is carried out by the weight of the arm, with the possibility of continuous regulation by the oil damper butterfly valve. When the cut is finished the band saw drive automatically switches off. To facilitate easy arm uplift the machine is equipped with adjustable tension springs that allow for setting of optimum force required for the arm uplift according to characteristics of the material to be cut. Vice system contributes to versatility of use by providing bilateral continuous setting of the cutting angle within the ranges 60° to the right and 45° to the left. The turntable rotates along with the saw band. Thanks to that the saw band does not cut into the loading surface of the vice.

- Robust machine framework composes of castings from grey cast iron and therefore ensures vibration absorption.

- Modern concept of the band saw arm allows for large cutting ranges in upright and angular cuts.

- Simple locking and adjusting of the desired cutting angle on the angle scale with stops fixed at 45°, 60° and 90°.

- Massive quick-clamping vice ensures easy and reliable material clamping.

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with worm gearbox.

- Three-phase two-speed motor (400 V) allows for the selection of band speed between 40 and 80 m/min.

- The machine is connected to a complete cooling system with a high-performance pump and possibility of regulating the

- flow on both guiding heads independently. Coolant tank with a pump is placed in the base of the machine.

- Easy control by ergonomically placed controls (electrical and hydraulics) on the base of the machine.

- The machine is equipped with a 250 mm workpiece stop.

| 90° | -45° | +45° | +60° | |

|

250 | 170 | 200 | 130 |

|

240 | 150 | 185 | 110 |

|

300 x 185 | 185 x 110 | 190 x 180 | 125 x 110 |

| Main motor | 400 V, 50 Hz, 0,9/1,4 kW |

| Pump motor | 400 V, 50 Hz, 0,05 kW |

| Saw blade speed | 40/80 m/min. |

| Working height of vice | 900 mm |

| Coolant tank | cca 15 l |

| Machine dimensions (min.) | 1630 x 750 x 1420 mm |

| Machine dimensions (max.) | 1840 x 1680 x 1990 mm |

| Machine weight | 285 kg |

*) Is always a part of the conveyor.

Note: You can connect M280 behind the cut as a conveyor only if angular cutting isn‘t required.

-

Auto-start descent of the arm

In standard machines, the control valve of the arm descent has to be shut after the arm uplift and by the next arm descent, the descent speed has to be set again. In this version, the control valve is additionally fitted with an electro-hydraulic valve, which remains after the arm uplift in the set position. After saw blade start, it is automatically released and the arm descents into the cut at a set speed. Thus, setting of the descent speed for each cut falls off. This significantly eliminates operator error and thus protects the saw blades, and increases also productivity of the machine. An ideal help when cutting material in larger series.

-

Universal band saw is appraised for general use in continuous uninterrupted production plants and in workshops (work on locks, maintenance) as well. Industrial band 27 x 0.9 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel.

The band saw arm uplift is manual; the feed into cut is carried out by the weight of the arm, with the possibility of continuous regulation by the oil damper butterfly valve. When the cut is finished the band saw drive automatically switches off. To facilitate easy arm uplift the machine is equipped with adjustable tension springs that allow for setting of optimum force required for the arm uplift according to characteristics of the material to be cut. Vice system contributes to versatility of use by providing bilateral continuous setting of the cutting angle within the ranges 60° to the right and 45° to the left. The turntable rotates along with the saw band. Thanks to that the saw band does not cut into the loading surface of the vice.

- Robust machine framework composes of castings from grey cast iron and therefore ensures vibration absorption.

- Modern concept of the band saw arm allows for large cutting ranges in upright and angular cuts.

- Simple locking and adjusting of the desired cutting angle on the angle scale with stops fixed at 45°, 60° and 90°.

- Massive quick-clamping vice ensures easy and reliable material clamping.

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with worm gearbox.

- Three-phase two-speed motor (400 V) allows for the selection of band speed between 40 and 80 m/min.

- The machine is connected to a complete cooling system with a high-performance pump and possibility of regulating the

- flow on both guiding heads independently. Coolant tank with a pump is placed in the base of the machine.

- Easy control by ergonomically placed controls (electrical and hydraulics) on the base of the machine.

- The machine is equipped with a 250 mm workpiece stop.

-

90° -45° +45° +60°

250 170 200 130

240 150 185 110

300 x 185 185 x 110 190 x 180 125 x 110 Main motor 400 V, 50 Hz, 0,9/1,4 kW Pump motor 400 V, 50 Hz, 0,05 kW Saw blade speed 40/80 m/min. Working height of vice 900 mm Coolant tank cca 15 l Machine dimensions (min.) 1630 x 750 x 1420 mm Machine dimensions (max.) 1840 x 1680 x 1990 mm Machine weight 285 kg -

*) Is always a part of the conveyor.

Note: You can connect M280 behind the cut as a conveyor only if angular cutting isn‘t required. -

-

Auto-start descent of the arm

In standard machines, the control valve of the arm descent has to be shut after the arm uplift and by the next arm descent, the descent speed has to be set again. In this version, the control valve is additionally fitted with an electro-hydraulic valve, which remains after the arm uplift in the set position. After saw blade start, it is automatically released and the arm descents into the cut at a set speed. Thus, setting of the descent speed for each cut falls off. This significantly eliminates operator error and thus protects the saw blades, and increases also productivity of the machine. An ideal help when cutting material in larger series.