DX-NC

We confirm receipt of noncommittal demand

Demanded machine: DX-NC

Company:

Kontaktní osoba:

VAT:

Adresa:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to website

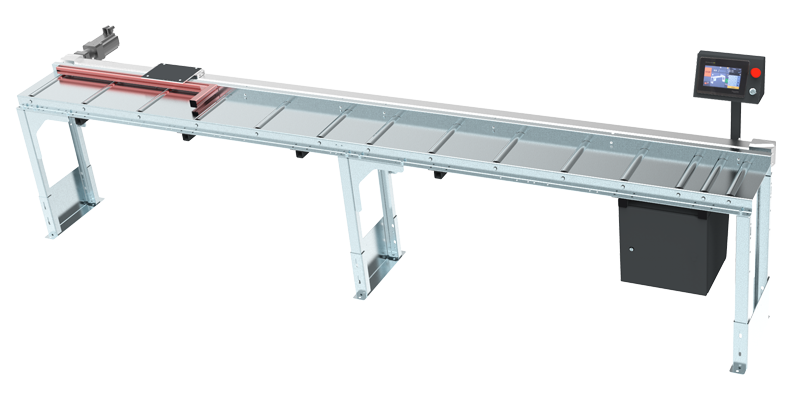

Automated NC Material Pusher device is designed for precise feeding of profile materials and light solid materials of small diameters into the bandsaw. The base comprises of massive roller conveyor D, with attached quality industrial linear axle. Servo motor ensures high speed and measuring accuracy of 0,1 mm. Feeding trolley moves along linear guiding system. The system allows precise feeding of the materials up to 500 kg of weight. For example: solid material dia 110 mm, length 6m, or HEB profile 280, length 6m. User´s friendly device control is done via large HI-RES colour touch screen. Capability of storing frequently used length in memory. It´s an intelligent device which regulates feeding speed in harmony with material weight and prevents destruction of feeding device by overloading. To prevent movement of the fed material, the feeding jaw can be fitted with a clamping device suitable for the material being cut.

Possibility of easily switching the machine to stop/pulling material/pushing material modes. It serves as an ideal device to accompany our bandsaw machines Pilous ARG 235 - ARG 300. The package includes system with Automated NC Gauging, feeding system of appropriate length, control panel, conveyor.

| measured length [mm] | total length [mm] | |

|---|---|---|

| DX-NC 3m | 2400 | 3000 |

| DX-NC 4m | 3400 | 4000 |

| DX-NC 7m | 6400 | 7000 |

| Control | Using servomotor BMH1001 |

| Motor power | 1.26 kW |

| Speed | 4000 rpm |

| Control interface | Large 7" touch screen |

| Feeding accuracy | 0.1 mm |

| Conveyor length | 3 m, 4 m, 7 m |

| Measured length | 2400 mm, 3400 mm, 6400 mm |

| Roller width | 300 mm |

| Roller diameter | 60 mm |

| Load capacity | 300 kg/m |

| Maximum weight of pushed workpiece | 500 kg |

| Carriage mounting | Linear guide |

-

Automated NC Material Pusher device is designed for precise feeding of profile materials and light solid materials of small diameters into the bandsaw. The base comprises of massive roller conveyor D, with attached quality industrial linear axle. Servo motor ensures high speed and measuring accuracy of 0,1 mm. Feeding trolley moves along linear guiding system. The system allows precise feeding of the materials up to 500 kg of weight. For example: solid material dia 110 mm, length 6m, or HEB profile 280, length 6m. User´s friendly device control is done via large HI-RES colour touch screen. Capability of storing frequently used length in memory. It´s an intelligent device which regulates feeding speed in harmony with material weight and prevents destruction of feeding device by overloading. To prevent movement of the fed material, the feeding jaw can be fitted with a clamping device suitable for the material being cut.

Possibility of easily switching the machine to stop/pulling material/pushing material modes. It serves as an ideal device to accompany our bandsaw machines Pilous ARG 235 - ARG 300. The package includes system with Automated NC Gauging, feeding system of appropriate length, control panel, conveyor.

measured length [mm] total length [mm] DX-NC 3m 2400 3000 DX-NC 4m 3400 4000 DX-NC 7m 6400 7000 -

Control Using servomotor BMH1001 Motor power 1.26 kW Speed 4000 rpm Control interface Large 7" touch screen Feeding accuracy 0.1 mm Conveyor length 3 m, 4 m, 7 m Measured length 2400 mm, 3400 mm, 6400 mm Roller width 300 mm Roller diameter 60 mm Load capacity 300 kg/m Maximum weight of pushed workpiece 500 kg Carriage mounting Linear guide