KO-NC

We confirm receipt of noncommittal demand

Demanded machine: KO-NC

Company:

Kontaktní osoba:

VAT:

Adresa:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to website

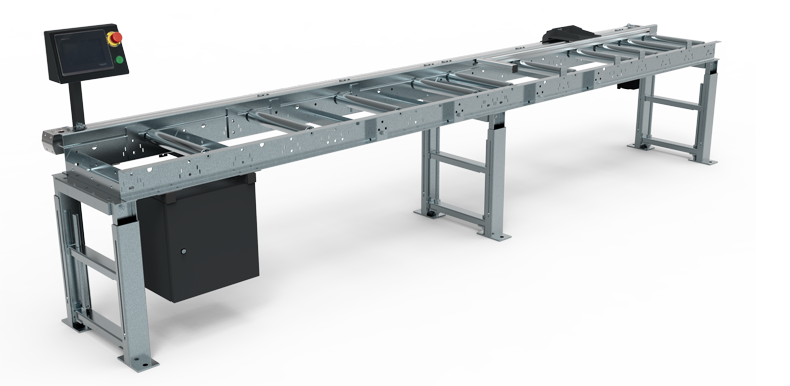

Automated NC Gauging device is designed for measuring profile materials and light solid materials of small diameters. The base comprises of massive roller conveyor K 400 or K 520, with attached quality industrial linear axle. Servo motor ensures high speed and measuring accuracy of 0,1 mm. Backstop trolley moves along linear guiding system. User´s friendly device control is done via large HI-RES colour touch screen. Capability of storing frequently used length in memory, ability of backstop to jump aside off the material before cutting. Intelligent gauging device with NC control enables the backstop to jump aside and back to set position when the material hits the backstop extensively (when overloaded). Gauging device KO-NC could be mounted on the roller conveyors types K 400 and K 520. It serves as an ideal device to accompany our semiautomatic bandsaw machines Pilous ARG 300 - ARG 500.

The package includes backstop system with Automated NC Gauging, feeding system of appropriate length, control panel, conveyor.

| measured length [mm] | total length [mm] | |

|---|---|---|

| KO-NC 3m | 2400 | 3000 |

| KO-NC 4m | 3400 | 4000 |

| KO-NC 7m | 6400 | 7000 |

| Control | Using servomotor BMH1001 |

| Motor power | 1.26 kW |

| Speed | 4000 rpm |

| Control interface | Large 7" touch screen |

| Feeding accuracy | 0.1 mm |

| Conveyor length | 3 m, 4 m, 7 m |

| Measured length | 2400 mm, 3400 mm, 6400 mm |

| Roller width | 400 mm, 520 mm |

| Roller diameter | 58 mm |

| Load capacity | 500 kg/m |

| Maximum weight of pushed workpiece | 500 kg |

| Carriage mounting | Linear guide |

-

Automated NC Gauging device is designed for measuring profile materials and light solid materials of small diameters. The base comprises of massive roller conveyor K 400 or K 520, with attached quality industrial linear axle. Servo motor ensures high speed and measuring accuracy of 0,1 mm. Backstop trolley moves along linear guiding system. User´s friendly device control is done via large HI-RES colour touch screen. Capability of storing frequently used length in memory, ability of backstop to jump aside off the material before cutting. Intelligent gauging device with NC control enables the backstop to jump aside and back to set position when the material hits the backstop extensively (when overloaded). Gauging device KO-NC could be mounted on the roller conveyors types K 400 and K 520. It serves as an ideal device to accompany our semiautomatic bandsaw machines Pilous ARG 300 - ARG 500.

The package includes backstop system with Automated NC Gauging, feeding system of appropriate length, control panel, conveyor.

measured length [mm] total length [mm] KO-NC 3m 2400 3000 KO-NC 4m 3400 4000 KO-NC 7m 6400 7000 -

Control Using servomotor BMH1001 Motor power 1.26 kW Speed 4000 rpm Control interface Large 7" touch screen Feeding accuracy 0.1 mm Conveyor length 3 m, 4 m, 7 m Measured length 2400 mm, 3400 mm, 6400 mm Roller width 400 mm, 520 mm Roller diameter 58 mm Load capacity 500 kg/m Maximum weight of pushed workpiece 500 kg Carriage mounting Linear guide